Inventory control leads the way for a wide range of businesses to drive more profitability.

Good stock control leads to better cost control and quick customer demand satisfaction. To

stay on top of your inventory control, RFID in manufacturing allows you to track every edge

of the inventory materials at a click.

Well, keeping track and staying ahead of inventory is a time-consuming process, but RFID tracking has made it more convenient.

However, with recent advancements in RFID technologies, you can access the best technology that forms a dynamic, automatic system that does not create additional demand for manual work but increases the degree of accuracy, safety, and speed of operation.

Using RFID for inventory management has increased accuracy by up to 13% compared to

conventional inventory monitoring systems and hand inventory checks. This article explores

how these innovations change the game regarding inventory management and lay a

foundation for more intelligent supply chain operations.

What is RFID Technology?

Radiofrequency identification is the top technology of data transfer wherein objects are

identified using electromagnetic waves from or to a tag. Three main parts define the system:

RFID Tags:

Tiny chips that store unique identification information about an item. These can be either active (run with the help of a battery for long-range communication) or passive (running off the reader’s power to transmit data).

Readers:

They send radio waves that activate RFID tags and receive saved data. Applications require handheld or stationary readers.

Antennas:

These transmit the signal between the readers and the tags, resulting in a

successful data transfer.

Applications in Inventory Management.

RFID technology has become accepted as essential to retail, manufacturing, and logistics. RFID is used in warehouses to automatically track items, maintain accurate stock tallies, and allow real-time updates on stock movements. For example, RFID is used to monitor shelf stock levels in retail businesses, and for logistics companies, it serves to follow goods in the supply chain

Role of Drones in Inventory Management

Drones are among the most effective instruments for revolutionizing inventory management. They automate all processes and provide real-time data on a business’s operations. With sophisticated sensors, cameras, and GPS systems, drones are peculiar to warehouses and distribution centres in many ways.

Automating Tasks

Typically, an inventory audit entailed considerable human effort: workers had to count and scan items manually. These processes are automated with drones, drones that fly over storage areas and use cameras or RFID readers to capture the data. Because there are fewer items, the time and resources required for inventory checks decrease, greatly freeing a business to focus on more strategic activities.

Reducing Errors

Handy manual inventory management is risky due to human errors of miscounts and misplaced items. But drones do away with these risks by carrying out things with precision. For instance, drones can make it scan every item in warehousing without missing any element, which is one of the fundamental reasons that guarantee authentic accounts are kept.

Improving Safety

Safety hazards in warehouse environments include areas with high shelving or dangerous materials. And because drones can reach places humans can’t, such as ceilings or dangerous zones, they mitigate these risks while accessing and scanning inventory.

Providing Real-Time Data

Sensor-equipped drones connected to warehouse management systems (WMS) share real-time inventory levels and locations. Having this capability, businesses can quickly react to inventory shortages or surpluses to improve their decision-making and customer satisfaction.

Tracking Inventory Levels

Drones fly through storage areas and can check the stock level quickly and efficiently. This is especially good for large warehouses where manual counts would take days. In addition, drones can find low-stock inventory items, enabling drivers to avoid stockouts.

Making Space Work Smarter

Optimization of storage layouts in warehouses is a widespread pain point. Due to their size,

drones can survey areas through tight spaces, allowing insights into often unused or poorly

used areas. This allows businesses to redesign their storage systems for maximum efficiency

and, therefore, increase storage capacity.

Get FREE Consultation

When Drones and RFID Work Together?

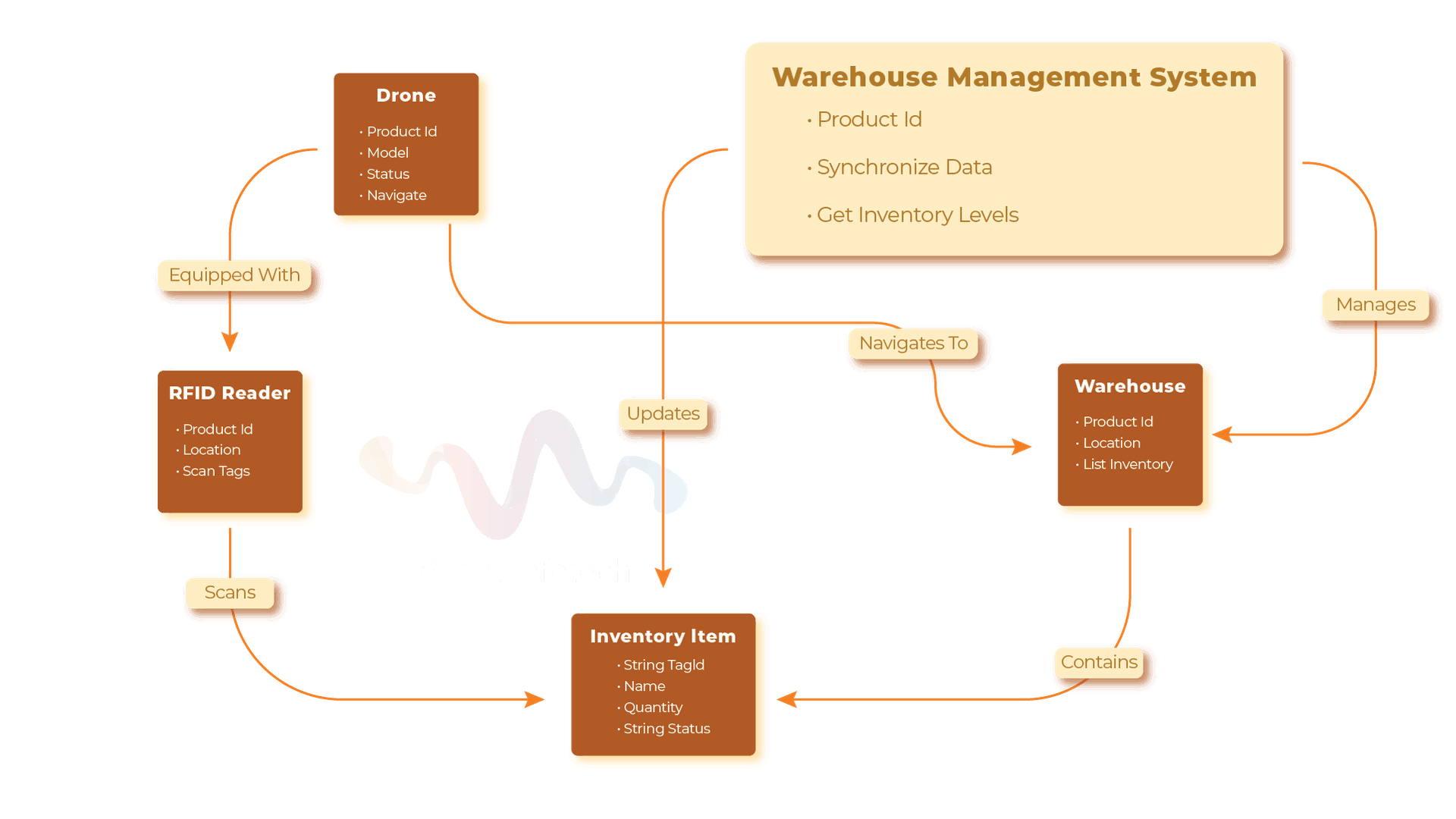

The combination of drones with RFID technology will facilitate the inventory management

system to become seamless and efficient. Flying drones equipped with RFID readers also

leverages UAVs' mobility with the precision of RFID to provide a game-changing option for

warehouses and industrial facilities.

Process Flow

● Drone Navigation: Drones fly from one pre-mapped inventory zone to another using GPS and sensors onboard. This allows systematic coverage of all storage space.

● RFID Tag Scanning: The drone's RFID reader picks up the tags on the inventory items as they move through the warehouse. Readers collect item locations, quantities, and status data.

● Data Synchronization: Moving forward, the scanned data is synchronized with the

warehouse management system (WMS), providing you with real-time inventory

levels.

Use Cases Across Industries

● Retail: Drones and RFID are used by retailers to perform quick and accurate stock audits to always have the right products on the shelves.

● Logistics: With these technologies, shipments in distribution centres are tracked to avoid delays and ensure timely deliveries.

● Manufacturing: Raw material and finished goods tracking allows manufacturers to plan production efficiently and optimize inventory.

In addition to the significant increase in inventory process time, security improves, with diminished theft or loss risk, as this blog mentions

Key Benefits of Combining Drones and RFID

Increased Efficiency

With manual processes, scanning large volumes of inventory would take hours or days, but

drones and RFID readers can scan large volumes of inventory in minutes. Thus, this efficiency

guarantees timely inventory replacement and efficient order delivery.

Enhanced Accuracy

Fatigue or oversight can lead to many errors in manual inventory counts. Drones and RFID track inventory with 100% accuracy by working precisely.

Cost Savings

Automating inventory tasks can save businesses massive amounts of labour costs.

Furthermore, by reducing errors and improving accuracy, one can lessen the financial

burden of discrepancies and stockouts.

Scalability

The combination of drones and RFID is versatile, whether in small warehouses or industrial

zones. It can scale operations without sacrificing efficiency or accuracy.

Challenges of implementing drones and RFID for inventory

Despite their numerous benefits, implementing drones and RFID for inventory management

comes with specific challenges:

Initial Investment

The initial costs of purchasing drones, RFID readers, and accompanying infrastructure can be

high for small businesses. Long-term efficiency gains and savings rarely offset these costs

Regulatory and Operational Hurdles

Operating drones is strictly controlled and involves permissions and safety standards, among

other things. Businesses must be sure they are complying to avoid legal issues. Additionally,

a warehouse may need to be restructured to accommodate drone navigation.

Skilled Operators

Drone and RFID systems require specialist operators and maintenance facilities. Costs for the

initial implementation may include hiring trained personnel or investing in training

programs

Maintenance Needs

These drones, RFID readers, and supporting systems must be maintained regularly to avoid

downtime and ensure seamless operations. This further increases the ongoing costs of using

these technologies.

Take Your Warehouse to New Heights!

Implement cutting-edge drone and RFID technology for seamless inventory management. Schedule a consultation now!

Future of Inventory Management with Drones and RFID

The future holds enormous promise for the continuous development of drones and RFID

technology to transform inventory management.

Innovations on the Horizon

AI-equipped drones can be navigated more intelligently around obstacles and are optimized

for the shortest flight path. Moreover, increased data capacity and durability of RFID tags will

further increase the inventory tracking capability

IoT Integration

The idea is to have a fully automated inventory ecosystem by integrating drones and RFID to

IoT devices. This would allow real-time monitoring and decision-making with data from

multiple sources.

Widespread Adoption

These technologies will become more affordable and will be increasingly adopted across industries. Drones and RFID are two technologies businesses of all types, from healthcare to retail, will use for more competent inventory management.

Conclusion

The merging of drones with RFID technology is transforming inventory control by offering companies a more precise, cost-effective, and efficient option. While RFID tags guarantee exact inventory updates, drones can swiftly and effectively cover large warehouse areas by automating the inventory monitoring process. This mix lowers human mistakes, improves security, and simplifies processes, thus saving large amounts of money and raising output.

Moreover, the scalability of this solution qualifies it for companies of all kinds, from tiny warehouses to huge industrial complexes. As technology develops, the possibilities for even more remarkable inventory control using drones and RFID are enormous. Companies that use this creative strategy streamline their inventory systems and gain a competitive advantage in a market driven by data and growing speed. Businesses should examine how RFID and drones can revolutionize their inventory control systems.

FAQs Related To RFID Inventory Management in Manufacturing

Drones and RFID allow for real-time data and automation of inventory tracking, avoiding

mistakes from people and providing accurate stock records.

Here are the list of best sectors that benefits the most from the efficiency of RFID and Drone

technologies:

Retail, Logistics, Manufacturing, Healthcare.

Though the initial outlay is significant, small firms find the solution cost-effective based on

long-term savings in personnel expenses, mistakes, and operational efficiency.

Drone flight permissions and safety standards may vary at the regional level, and businesses

must comply with regulations.

While drones can work on several layouts, some warehouses may need modifications to make them work well with drones.

| About Author

Rajesh R

A seasoned IT Integrations and ERP Solution Architect boasts over a decade's expertise in revolutionizing business processes through cloud-based ERP and MIS software solutions. Proficient in leveraging avant-garde technologies such as Blockchain, Al, IoT, etc in crafting bespoke software solutions. His extensive background encompasses tailor-made software solutions across diverse industries like Sales, Manufacturing, Food Processing, Warehouse Operations→ and B2B Businesses. Rajesh excels in engineering and deploying enterprise-grade business software, playing a pivotal role in Business Solution Consulting and designing intricate software solution architectures for many Fortune 500 enterprises.

Schedule Consultation with Rajesh Schedule Now