Warehouse Management System

Using a centralized warehouse management software solution, you can streamline your warehouse operations across multiple locations. Flexible, automated WMS solution to help in market adaptation.

What Is Warehouse Management Software?

In today’s dynamic world, consumers want to go anywhere to fulfill their buying and returning needs. To meet these needs, warehouses must respond to the warehouse management system as quickly as possible. The industry-leading cloud-based warehouse management software prepares you for the upcoming demands of supply chains. It also aligns inventory management systems with modern purchasing methods and offers real-time visibility via smartphone and browser; the only critical need is the Internet.

Get FREE Consultation

WMS Software Businesses Needs

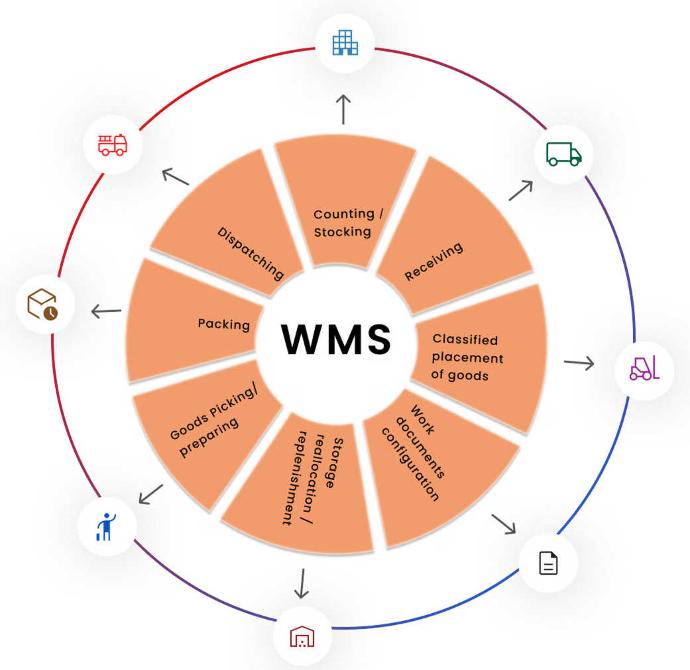

Warehouse management systems (WMS) consist of software and processes that allow visibility to the organizations to control and manage warehouse supply from the distribution center to the store.

WMS systems are made to support the needs of a global supply chain or to ensure that goods and supply should move in a very efficient and cost-effective way, including manufacturing, asset-intensive, distribution, and service businesses. These warehouses also enable companies to accelerate their labor, space utilization, and equipment investments by analyzing and optimizing material flows and resource usage. WMS follows many functions to enable these movements without any hindrance, including inventory tracking, picking, receiving, and putting away.

Evolution Of Warehouse Management System(WMS)

The origins of warehouse management systems can be traced back to the early 1960s when companies began using computers to automate and optimize their warehouse operations. At this time, companies were using mainframe computers to manage inventory and order fulfillment, and the first warehouse management software was developed to support these operations.

In the 1980s and 1990s, advances in computer technology and the proliferation of personal computers led to the development of more advanced warehouse management systems. These systems were designed to be used on personal computers and were more user-friendly than the mainframe systems of the past.

In the 21st century, the growth of e-commerce and the increased demand for fast and efficient order fulfillment have led to the development of even more advanced warehouse management systems. These systems are designed to handle the high volume of orders and the complex logistics involved in e-commerce operations. Many modern WMS systems also can integrate with other business systems, such as an enterprise resource planning (ERP) system or a customer relationship management (CRM) system.

Efficiently manage your warehouse operations with our Custom WMS system. Boost productivity and streamline processes with Warehouse Management Software. Speak with our WMS Experts to clear all your doubts.

Features of Warehouse Management Software

Inventory Management

A WMS can help companies track inventory levels and locations within the warehouse using barcode scanners or RFID technology. This can help reduce errors and improve the accuracy of inventory records.

Order Management

A WMS can help companies manage the flow of orders through the warehouse, including routing orders to the appropriate picking locations, scheduling and tracking shipments, and generating reports.

Integration With Other Systems

WMS systems offer integration with other business systems, such as enterprise resource planning (ERP) systems and transportation management systems (TMS). This can help companies streamline their operations and improve the flow of information between different systems.

Customizable Reporting & Analytics

Many WMS systems offer customizable reporting and analytics tools to help companies better understand their warehouse operations and make informed decisions.

Mobile Support

Many WMS systems offer mobile support, allowing employees to access the system using smartphones or tablets. This can help improve the efficiency and flexibility of warehouse operations.

Labour Management

Robust labour management that streamlines operations by enabling precise personnel tracking and resource optimization. Through features like QR code-based clock-ins and real-time hour tracking, it helps with efficient workforce management.

Overall, the specific features of a warehouse management system will depend on the needs and goals of a company, as well as the size and complexity of the warehouse. It is important for companies to prudently evaluate their needs and choose a system that is good for their business.

The Warehouse inventory management system domain is presented using domain model feature diagrams that show the features of smart warehouses. Business houses need different warehouse models, whereas this model defines both traditional and modern smart warehouses.

Types of Warehouse Management Systems

Basic WMS

Basic WMS systems provide basic functionality such as inventory tracking, receiving, and order picking. They may also include some basic reporting and analysis capabilities.

Advanced WMS

Advanced WMS systems offer more comprehensive functionality and may include features such as real-time tracking, demand forecasting, and optimization of warehouse layout and processes.

Cloud-based WMS

Cloud-based WMS systems are hosted on a remote server and are accessed on the Internet. This type of WMS is generally easier to implement and maintain than on-premises systems.

Integrated WMS

Integrated WMS systems are designed to work seamlessly with other systems, such as enterprise resource planning (ERP) or transportation management systems (TMS).

Standalone WMS

Standalone WMS systems are self-contained systems that are not integrated with other systems. They may be suitable for smaller warehouses or companies that do not have complex operations.

Benefits Of A Modern Cloud-Based Warehouse Management System

Digital technology and the internet are transforming the way customers buy, reaching the demands fast, disrupting and adding complexities to the supply chains in the market. To fulfill these operations, they must develop their own digitally connected solution. Moving to the modern cloud-based (warehouse management system) can connect the consumer with a fulfillment solution that offers real-time visibility, market reactivity, and scalability.

- Advantages: Faster Implementation: Traditional WMS can take months to implement, but cloud computing can be completed in weeks, depending on the complexities. Cloud technology also eradicates the need to pay for the hardware and software or hire IT specialists to maintain the system.

- Reduced Operational Costs: Managing the WMS does not require customizations and modifications. It lowers the upfront costs and sometimes ongoing costs than on-premises systems. A WMS can help companies plan and execute efficient warehouse layouts, reducing the time and effort required to find and retrieve items. This can result in cost savings through reduced labor and equipment costs.

- Increased Efficiency and Productivity: By automating and streamlining tasks, a WMS can help companies improve the efficiency and productivity of their warehouse operations.

- Customizable Reporting and Analytics: Many WMS systems offer customizable reporting and analytics tools to help companies better understand their warehouse operations and make informed decisions.

Are you looking to improve the efficiency and organization of your warehouse operations?

Look no further than Silent Infotech’s expert Warehouse Management development team. Our team of experienced consultants will work with you to design and implement a custom system tailored to your specific needs and goals. Don’t let disorganization and inefficiency hold your business back any longer. Contact Silent Infotech today to schedule a consultation and start streamlining your warehouse operations. Fill details below to discuss more.

Futuristic Smart Warehouse Management Technologies:

Smart warehousing technology refers to the use of advanced technologies to optimize and automate various processes in a warehouse. Use of smart warehousing technology can help warehouses improve their operations and reduce costs, while also increasing customer satisfaction by providing faster and more accurate fulfillment of orders. These technologies can include:

Warehouse Automation

This refers to the use of robotic systems and automated equipment to handle tasks such as packing, sorting, and transportation of goods within a warehouse. This can help increase efficiency and accuracy, while also reducing the need for manual labor.

Voice-picking Technology

This involves using voice recognition software and headsets to allow warehouse workers to pick and pack items by speaking aloud, rather than manually scanning barcodes or manually entering data. This can reduce errors and increase productivity.

Mobile Devices

Smartphones, tablets, and other mobile devices can be used in warehouses to track inventory with RFID, receive and process orders, and communicate with other workers.

AI-integrated Warehouse

Warehouses can use artificial intelligence (AI) and machine learning to analyze data and make more informed decisions about inventory management, order fulfillment, and other processes. AI helps to improve efficiency, leading to increased customer satisfaction and competitive advantage.

IoT Integration in Warehouse

The Internet of Things (IoT) refers to the interconnected network of physical devices, vehicles, and other objects that are embedded with sensors, software, and network connectivity, allowing them to collect and exchange data. In a warehouse, IoT devices can be used to track the location and status of goods, as well as monitor equipment and other assets.

AR & VR Apps

Augmented reality (AR) and virtual reality (VR) apps can be used in warehouses to provide workers with real-time information, training, and guidance. For example, AR apps can display instructions or visualizations overlaid on the real world, while VR apps can simulate real-world scenarios for training purposes.

Warehouse Robots

Warehouses can also use robots to perform tasks such as moving and sorting items, loading and unloading trucks, and transporting goods between different areas of the warehouse. These robots can work alongside human workers to increase efficiency and productivity.

Blockchain Technology

Blockchain technology is used to provide transparency and traceability in supply chain management. This technology can be used to track products and materials from production to delivery, providing a complete and secure record of the supply chain.

Predictive Maintenance

Predictive maintenance and quality control systems use data and analytics to predict when equipment will need maintenance or repair. This can help to reduce downtime and improve equipment lifespan.

Use Cases of WMS in Different Industries

A WMS can be used in many different ways, depending on a company’s specific needs and goals. Some typical usage applications of a WMS include:

- Receiving and storing goods: A WMS can help companies manage the process of receiving and storing goods in the warehouse, including tracking the location of goods, updating inventory records, and generating reports on the status of inbound shipments.

- Picking and packing orders: A WMS can help companies manage the process of picking and packing orders for shipment, including routing orders to the appropriate picking locations, tracking the status of orders, and generating labels and other shipping documents.

- Shipping and tracking orders: A WMS can help companies manage the process of shipping orders, including scheduling and tracking shipments, generating reports on the status of outbound shipments, and integrating with transportation management systems (TMS) to optimize the flow of goods.

- Managing warehouse layouts: A WMS can help companies design and optimize the layout of the warehouse, including the placement of goods and equipment, to improve efficiency and reduce the time and effort required to find and retrieve items.

- Managing labor: A WMS can help companies track and optimize the use of labor in the warehouse by providing tools for scheduling, assigning tasks, and generating reports on labor productivity.

Bottom Line

A warehouse management system (WMS) is a software application that helps companies manage the operations of their warehouse or distribution center. It is designed to improve the efficiency and productivity of the warehouse by automating and optimizing various tasks, such as receiving, storing, and picking goods. The critical function of a warehouse management system is to record the arrival and departure of the product. The main features include recording the precise location of stock, optimizing the correct usage of available spaces, or coordinating the task for maximum efficiency. It also recommends the best storage location based on predefined business rules. These rules also include well-known inventory warehouse management rules such as FIFO (First in, First out) and LIFO (Last in, Last out), while optimizing storage face is a higher priority.

FAQs Related to Warehouse Management System

A WMS can help ensure the accuracy of inventory levels by providing real-time visibility into stock movements, allowing for regular cycle counting, and automating inventory updates with barcode scanning. Additionally, implementing strict inventory management policies and procedures can help ensure accuracy.

A WMS can improve customer service by providing real-time visibility into inventory levels, automating the picking and packing process, and providing detailed shipping and tracking information. This can lead to faster order fulfillment times, improved accuracy, and increased customer satisfaction.

Yes, WMS systems are designed to integrate with other systems such as accounting software, e-commerce platforms, and shipping systems. This allows for seamless data flow and a more efficient workflow.

While both WMS and ERP systems are designed to help businesses manage their operations, a WMS is specifically focused on warehouse management, while an ERP system is designed to provide an integrated view of all aspects of a business, including finance, manufacturing, and supply chain management.

To determine if a WMS is the right solution for your business, you should consider factors such as the size and complexity of your warehouse operations, the types of products you store and ship, and your current and future business goals. It’s also a good idea to research different WMS solutions and speak with Silent Infotech experts to understand their capabilities and limitations.

Warehouse management software can be used in a variety of warehouse environments, including distribution centers, manufacturing warehouses, and retail stores. However, it is important to choose a software that is tailored to the specific needs and requirements of your warehouse.

The cost of warehouse management software can vary greatly depending on the specific features and capabilities of the software. In general, prices can range from a few hundred dollars to several thousand dollars per month.

Some important features to look for in a warehouse management software include inventory tracking, real-time monitoring, data reporting, and integration with other business systems.

Warehouse management software can improve efficiency by automating many manual tasks, such as tracking inventory levels and generating reports. It can also help with organizing and storing goods, which can make it easier for warehouse workers to locate and retrieve items.

Warehouse management software is a type of software that helps businesses manage and optimize their warehouse operations. It can handle tasks such as tracking inventory levels, monitoring warehouse activity, and organizing and storing goods.