ERP Solution for Metal Fabrication Manufacturer

About Metal Fabrication Manufacturing Client

The client is a prominent name in the fabrication industry having expertise in heavy industry fabrication, lifting equipment, and industrial doors in the European region. They specialize in warehouse loading and unloading docks along with the metal Fabrication equipment needed by the various industries. Their manufacturing process begins after a job site visit and obtaining all the necessary measurements from the client. However, they were facing communication issues due to their manual process of managing data in Excel sheets and in hard copies of paper. There was a lack of availability of production status across various departments, and obtaining data from each department was a manual process. This led to miscommunication and uninformed decision-making. Sometimes, different departments were not informed about new quotations or lacked information related to resources. To address these challenges, we implemented an ERP solution that automated the process of receiving quotations, project management, field services management, and product warranty module integration. Upon implementation of cloud cloud-based ERP system helped them get real-time data on a single dashboard and ensured that all departments working more efficiently.

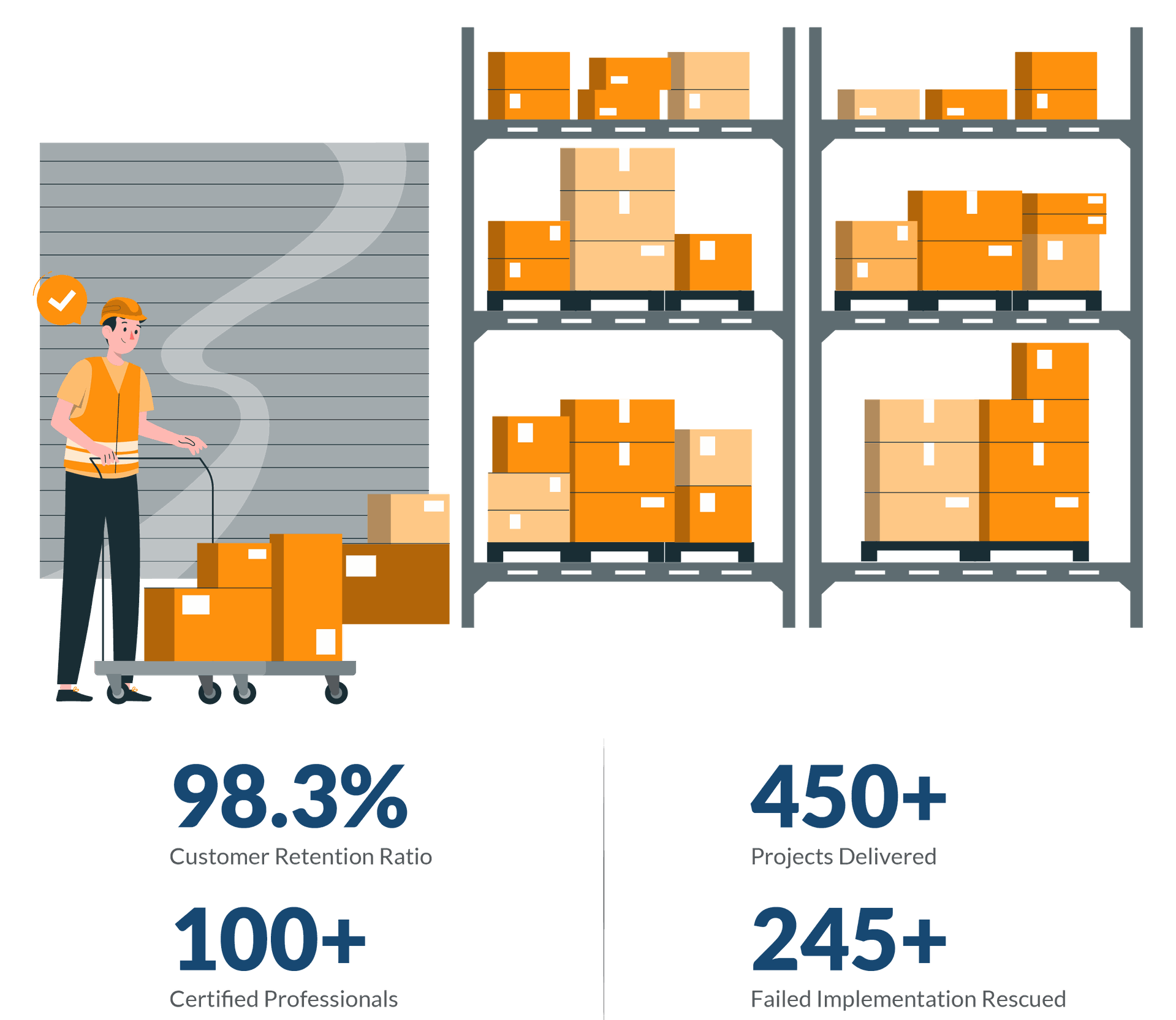

Key Outcomes & Success Metrics

20%

Faster customer response times with real-time production/dispatch updates.

15%

Reduction in planning errors via integrated project-resource modules.

25%

Increase in monthly quotations processed through automation.

Challenges Faced By Metal Fabrication Industry

- The organization was facing challenges in processing quotations as per demand due to the distributed work among departments and a manual process. There was lack of communication between departments resulting in delays in sending the final quotation to clients.

- The progress status of projects is not readily available and requires manual updates from each department. This process is time-consuming and delays the overall progress of work.

- Field data, including various measurements required for metal fabrication industries including manufacturing lifting equipment, and industrial doors, are collected in hard copy and distributed among departments, which consumes a significant amount of time.

- The warranty for products cannot be determined instantly due to the manual process, and all documents need to be checked to figure out the warranty.

- The organization was lacking proper planning as there is no real-time update from each department, resulting in delays and inefficiencies.

- The manual workflow for quotation preparation is taking up a lot of time, and the inflow of requirements is high compared to the monthly basis on which clients use to prepare quotations. As a result, the organization is unable to meet the monthly demand for the project inflow.

- Since client has custom metal fabrication manufacturing business model, the sales team faces the challenge of creating new quotations for each order. The absence of a quick reference to previous similar products and their prices makes the process time-consuming.

Benefit Of ERP Implementation Metal Fabrication Industry:

- By integrating project management software with fabricating business, the Client was able to bring all departments onto a single dashboard. This enabled them to notify all departments of new sales orders and quotation requirements instantly.

- Real-time insights into fabrication manufacturing progress were possible since all departments were internally linked. This led to better customer satisfaction as the client was able to provide accurate and real-time information to customers on production status and product dispatch dates.

- The field services management system helped to digitize the entire custom requirement of the customer, with all related data available in real-time from the field site. Employees at the field side could add data to the ERP system, and other team members could access this data in real-time.

- With streamlined process and real-time data availability, the client was able to process more quotations on a monthly basis and expand their business. Complete work reports, including hours spent by resources on the field, could be sent to the client instantly from the new ERP system.

- The planning module integrated with project management helped to obtain real-time resource availability data as well as current work progress. This allowed for more accurate planning of new metal fabrication project tasks and enabled the client to provide accurate deadlines to customers regarding product delivery.

- With the implementation of ERP system, sales team can now access historical data and can define specific parameters for each product category. These parameters allow for the identification of similar products based on their attributes. In just a single click, the system provides a comprehensive list of all relevant quotations, significantly speeding up the quotation process.