Problem Faced By Seafood Business Worldwide

In the seafood industry, several area-specific issues play a role – freshness, Sustainability, short ordering cycles, and slicing efficiency are the common issues that the fish industry is facing. The major issues faced by the Seafood Industry are :

- Freshness: The biggest challenge for the seafood industry is that they have overseas buyers who demand proof of the freshness of the seafood. The Industries are unable to prove the freshness as they do not have such an Integrated System of Traceability. Thus, traceability of seafood is now becoming a greater concern for buyers that are overseas and therefore they are not able to gain the trust in the shelf life of the Seafood.

- Condition Monitoring: Real-time monitoring of environmental conditions in storage and during transit is not available to save the loss of the food.

Are you involved in seafood or any other food industry and looking for ways to streamline your food supply chain and inventory management?

Our ERP experts can help! We can assist in ensuring that your food reaches the end customer while it is still fresh and delicious. Why not have a free ERP Consultation with our Experts? We can help to optimize your food business operation. Connect now!

Seafood ERP Solution

- We have refined the AI-based Seafood supply chain ERP where the seafood supplier can track and trace the freshness and quality of the seafood. We are providing supply chain planning, supplier scheduling, product configurator, orders to cash, purchasing, inventory, warehousing, and shipment.

- It is a Cloud-hosted solution that is a core business process in real-time and combined with open-source technology to ensure an efficient but fully customized ERP.

- We produced a cloud-based solution that combines the supplier’s relationship management process with the procurement process to cut the time delays and functional and geographical limitations.

- We offer complete track and trace, enabling individuals to access the complete record of products, from the origin to certifications and authentic documentation. By offering time-stamped and community consensus-based immutable data, we create a trustless environment, preventing product counterfeiting.

Learn More On SeaFood ERP Software

The Glimpse of Our Seafood ERP Solution

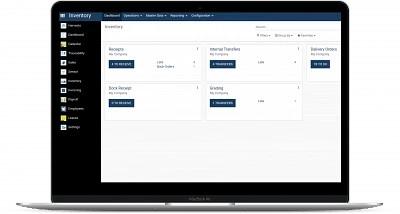

Real-time condition monitoring through IoT Sensors and RFID-enabled inventory management. Cloud-based Enterprise solution (ERP) customized as per the need of the Seafood Industry.

Custom CMS for Seafood Business

Catch management and Harvester’s profile management will let you take better decisions on the purchase. The number of catches and the details of the harvester is uploaded to the cloud.

IoT Dashboard

Condition Monitoring” will offer real-time data from the temperature sensors, Humidity sensors, Water Quality Sensors and DiOx Sensors in freezer storage or during transit.

RFID-Enabled Inventory Management

Automated RFID readers integrated with Odoo Backend via RFID IoT Gateway will eliminate the data entry about inventory and will keep track of inventory in an automated way. Eliminating human errors in stock management and real-time reporting right within your mobile phone will help you make better decisions.

Payroll Management

Integrated payroll with other modules will get everything in one place in terms of the financial aspect of your business.

Apart from basic Odoo operations for Payroll, this module enables Canadian businesses to generate the T4/T5 tax form electronically which can be submitted to the online govt. portal.

Validating the T4/T5 batch before the submission is a great feature in the app.

The module appends with the required fields that are marked by the CRA and validated, before submitting it to them electronically through their portal.

Electronic payments with RBC and Bank of Montreal

- Enable online payment for the customer and internal transfer.

- We’ve integrated electronic payment EFT for RBC(Royal Bank of Canada) and BMO(Bank of Montreal).

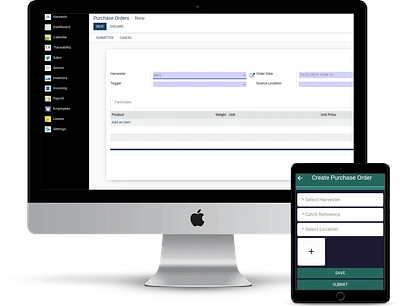

Purchase Order

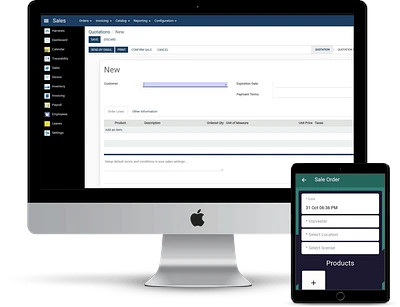

Sales Order

SeaFood Traceability Solution

Throughout the business process including the supply chain, it will offer you traceability to prove the freshness of the seafood and hence to better estimate the shelf life of the food.

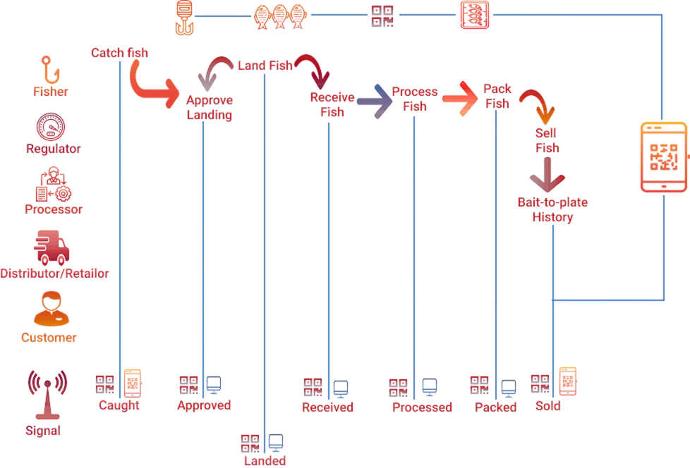

How Sea Food ERP Works

Ready to take your seafood or food business to the next level with a customized ERP solution? Fill out the form below and our team at Silent Infotech will be in touch to help you develop a solution that fits your unique needs and streamlines your operations. Don’t wait, take the first step towards a more efficient and profitable business today!

Features Of SeaFood ERP

Inventory Management

Serialized Inventory tracking based on storage containers. Real-time and Stock reporting.

Processing & Grading

Automated record keeping on grading and packaging

Traceability

RFID based automated check-in onto various inventory location allows a trace of the product through the purchase to logistics.

Mobile Application

Integrated Mobile apps avail creating purchase slips right at the wharf/dock using handheld devices.

Sales Management

From the main container, you can change the background to highlight features.

Condition Monitoring

Integrated IOT dashboard provides a real-time view of various sensors installed on storage locations measuring temperature & water quality.