RFID In Supply Chain Management & Logistics Industry

In today’s fast-paced global economy, efficient supply chain management is crucial for logistics companies’ success. With the rise of e-commerce and globalization, businesses face increased pressure to improve operational efficiency, enhance visibility, and ensure the smooth flow of goods from the point of origin to the end consumer. Many companies are adopting innovative technologies such as Radio Frequency Identification or

What is RFID?

RFID stands for Radio Frequency Identification, a technology that uses radio waves to identify and track objects automatically. It comprises tags, readers, and a backend system that processes and manages the collected data. RFID tags are small electronic devices that contain a microchip and an antenna. These tags can be attached to products, containers, or assets, enabling them to be uniquely identified and tracked throughout the supply chain.

How RFID Works In Supply Chain Management & Logistics Industry ?

Get FREE Consultation on RFID Integration

Benefits of RFID in Supply Chain & Logistics Industry

Improving Visibility & Transparency In The Supply Chain Industry:

- One of the significant challenges logistics companies face is the need for real-time visibility into the movement of goods. Traditional barcode systems require manual scanning, which can be time-consuming and prone to errors. On the other hand, RFID technology enables automated and accurate data capture, providing real-time visibility into the location, status, and condition of goods at each stage of the supply chain. This enhanced visibility allows companies to make informed decisions, improve operational efficiency, and respond quickly to any disruptions or delays.

Optimizing Warehouse & Inventory Management With RFID Integration

- RFID technology revolutionizes warehouse and inventory management by enabling accurate and efficient stock tracking. With RFID tags attached to products and assets, companies can automate inventory counting, reduce manual labor, and eliminate errors associated with manual data entry. RFID readers placed strategically throughout the warehouse can quickly scan and identify multiple items simultaneously, providing real-time inventory updates. This improves inventory accuracy, streamlines order fulfillment processes, and reduces stockouts or overstock situations, leading to better customer satisfaction and cost savings.

Enhancing Asset Tracking & WMS Management System

- Assets, such as containers, pallets, or reusable packaging, play a crucial role in the supply chain. RFID technology enables companies to track and manage these assets more effectively, improving asset utilization and reducing losses. By tagging assets with RFID tags, companies can quickly locate and track their movements, optimize asset allocation, and ensure timely returns. This reduces the need for manual searches and minimizes asset loss or theft, resulting in significant cost savings for logistics companies.

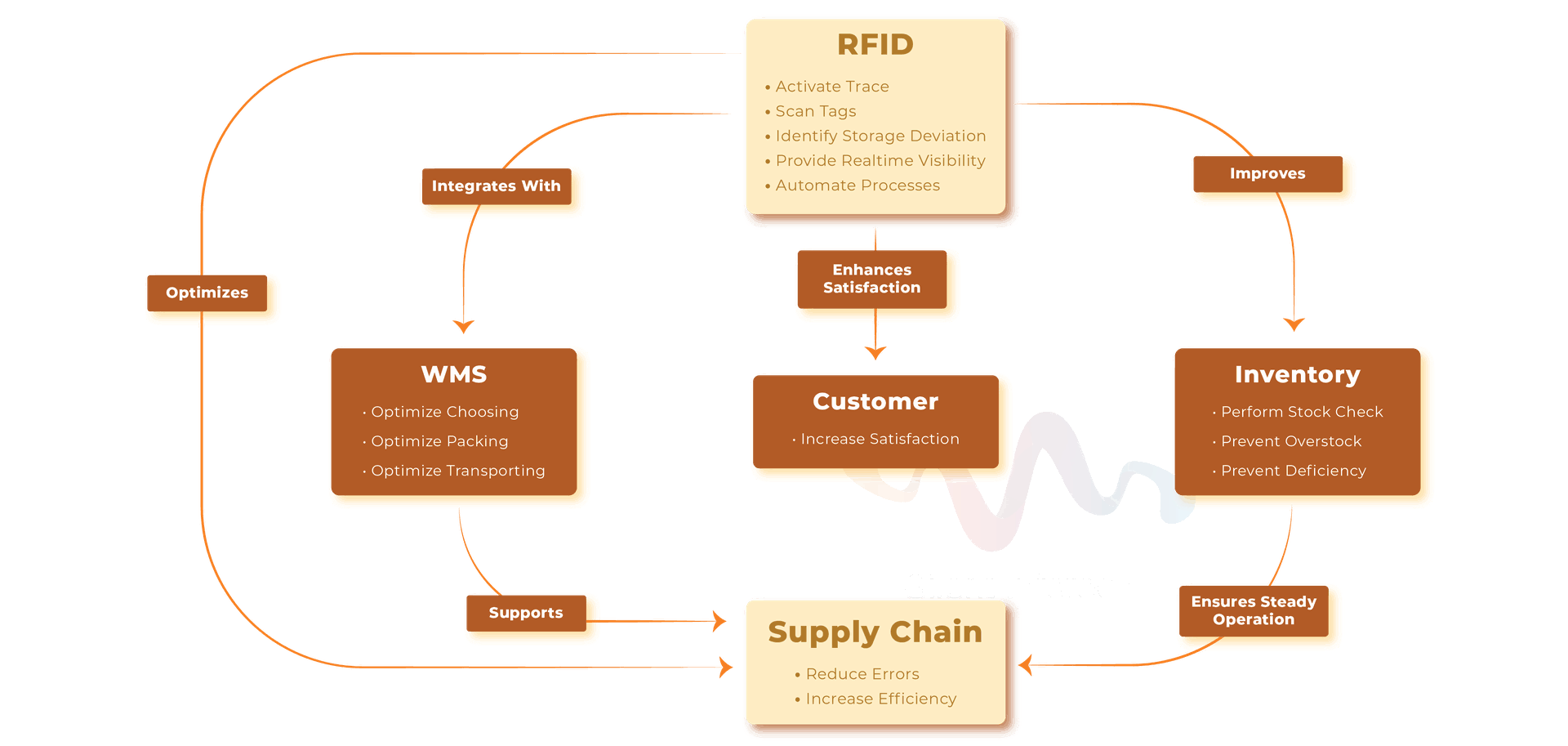

Increases The Efficiency

- RFID activates trace of real-time without line-off-Vion scan, fixed product movement and workflow. Integrated with WMS, optimizing choosing, packing and transporting, reducing labor costs and increasing productivity.

Speed Up Inventory Counts

- RFID scans several tags at the same time, eliminates manual counting, saving time and reducing errors. Accurate stock checks prevent overstood or deficiency and frees up resources for important tasks.

Corrects Lager Deviation

- RFID identifies and fixes the storage deviation in real time, improves the supply order, reduces waste and the customer increases satisfaction. Exact inventory ensures steady operation.

The Product Increases Access

- RFID provides real -time visibility, which helps companies to predict deficiency. It reduces empty shelves, improves customers' satisfaction and improves the efficiency of the supply chain.

Autches Receipt, Storage & Delivery

- RFID Supply chain processes automatically, ranging from reduced errors and labor costs. Fast, accurate orders meet increases customers' satisfaction and operating efficiency.

Upgrade your logistics and supply chain management with RFID technology. Contact us now to harness the power of real-time asset tracking and enhanced visibility for improved operations.

Incorporating RFID Into The Supply Chain Management Software

Integration:

- To successfully incorporate RFID technology into the supply chain, businesses must focus on integration. With seamless integration, the benefits of RFID can be fully realized. Instead of relying solely on technical tools, companies should understand that human effort and collaboration are essential.

Purchasing:

- Purchasing is a critical process in the supply chain, as it involves acquiring the necessary raw materials for manufacturing goods. Incorporating RFID technology into supply chain management offers real-time visibility into semi-finished and in-stock raw materials.

- RFID enables businesses to verify if the received shipment matches the order, reducing the time spent on the receiving stage. This verification process ensures that items can be swiftly moved to the production stage, accelerating the overall

manufacturing process. Operations:

- RFID scanners provide businesses with the ability to monitor the movement of goods in warehouses with ease. Real-time information about warehouse activities significantly improves inventory management. Companies can access up-to-date data for more efficient decision-making and streamlined operations.

Distribution:

- RFID technology assists transport companies in monitoring the quality and movement of goods throughout the distribution process. In scenarios where suppliers face challenging conditions, RFID allows businesses to assess whether alternative plans or contingencies must be implemented. By incorporating RFID, businesses can optimize distribution processes, ensuring timely delivery of goods to warehouses, manufacturers, or directly to consumers.

The Future Of RFID In Supply Chain Management & Logistics Industry

RFID technology has already significantly impacted the logistics and supply chain management industry, but its potential still needs to be exhausted. We can expect further improvements and innovations in RFID systems as technology advances. Some key developments to look forward to include:

Integration With Other Technologies:

- RFID can be integrated with emerging technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), and Blockchain. This integration will enable even greater automation, predictive analytics, and secure data sharing across the supply chain ecosystem.

Smaller, Cheaper, & More Versatile Tags:

- As RFID technology evolves, we can anticipate the development of more petite, cheaper, and more versatile RFID tags. This will make it easier to integrate RFID technology into a broader range of products, assets, and packaging materials. Smaller tags will also enable more discreet tagging, minimizing any impact on product design or aesthetics.

Enhanced Data Analytics Capabilities:

- With the increasing volume of data collected through RFID systems, there will be a greater focus on leveraging advanced analytics techniques to extract valuable insights. This will help logistics companies optimize operations, identify trends, predict demand, and make data-driven decisions to improve efficiency and customer satisfaction.

Improved Security & Privacy Features:

- As RFID technology becomes more prevalent, ensuring the security and privacy of data will be paramount. Future advancements may include more robust encryption methods, authentication protocols, and privacy safeguards to protect sensitive information throughout the supply chain.

Extended Applications Beyond Tracking:

- While RFID technology is primarily associated with tracking and inventory management, its potential applications extend beyond these areas. For instance, RFID can be utilized for product authentication, warranty tracking, quality control, and even in ensuring compliance with regulatory requirements. As the technology matures, logistics companies will explore and implement these additional use cases to further enhance their operations.

Conclusion About Using RFID In Supply Chain Industry

RFID technology has emerged as a game-changer in logistics and supply chain management. Its ability to provide real-time visibility, automate processes, and improve asset tracking and inventory management has proven invaluable for businesses striving to optimize their operations and enhance customer satisfaction. As technology advances, we can expect

FAQs Of RFID In Supply Chain Management

RFID (radio frequency identification) uses radio waves to automatically identify and

track objects. In supply chains, RFID codes enable products or assets in real-time

tracking without line-off-Vion scan.

The RFID supply chain improves visibility, adapts to inventory management, increases

the tracking of assets, reduces manual errors and speeds up operations as inventory

and ordering.

RFID automatically scans multiple tags, and ensures accurate storage levels, reduces

excess or stocking, and streamlines storage operations.

Yes, RFID can be integrated with current WMS to provide the original time -inventory

updates, adapt to picking and packing processes and improving the general storage

efficiency. But again, it depends on which WMS software you are using and does it allow

customization or integration with other systems.

RFID provides real -time tracking of goods at all stages of the supply chain, from

production to delivery, helps companies reduce delays and improve the decision.

Unlike barcode, RFID does not require Line-off-Vion scan, can read more tags at the

same time, and provide real-time data with more accuracy and speed.

RFID codes on assets such as containers or palettes enable realtime tracking, reducing

losses or theft and improving realtime tracking, which saves the cost of logistics

companies.

Yes, RFID reduces labor costs by automating processes such as inventory and tracking

of assets, reducing errors and improving general efficiency.

Industries such as retail, e-commerce, production, health care and logistics benefit from

RFID, especially with complex supply chains and high storage sales.

By ensuring accurate and timely delivery, by reducing errors and providing real -time

tracking updates, improving RFID customers' satisfaction and creating confidence in

logistics operations.

Silent Infotech offer RFID integration services, including consultation, implementation

and support, helping companies optimize the supply chain business with advance

software solutions.

Rajesh R

A seasoned IT Integrations and ERP Solution Architect boasts over a decade's expertise in revolutionizing business processes through cloud-based ERP and MIS software solutions. Proficient in leveraging avant-garde technologies such as Blockchain, Al, IoT, etc in crafting bespoke software solutions. His extensive background encompasses tailor-made software solutions across diverse industries like Sales, Manufacturing, Food Processing, Warehouse Operations→ and B2B Businesses. Rajesh excels in engineering and deploying enterprise-grade business software, playing a pivotal role in Business Solution Consulting and designing intricate software solution architectures for many Fortune 500 enterprises.

Schedule Consultation with Rajesh Schedule Now