The Future Of Manufacturing: How IIOT Is Transforming ERP?

Have you ever found yourself wondering how technology is revolutionizing our manufacturing practices? One key solution lies within the combination of ERP (Enterprise Resource Planning) and IIoT (Industrial Internet of Things) technologies.

In this article, we’ll look at how

IIOT and ERP: An Overview

The IIoT has revolutionized manufacturing industries worldwide through smart devices and machines to become part of production lines. It helps in collecting vast amounts of data that can help streamline production and improve overall efficiency. But for maximum benefit from such data collection processes, it must also integrate with ERP systems.

IIoT and ERP integration provides companies with an effective tool for data-driven decision-making, streamlining operations, and cutting costs. By linking IIoT devices with ERP systems, businesses gain real-time visibility into production processes, raw material inventory levels and customer demand data. Using this insight, you can make proactive changes, such as changing production schedules or cutting waste out. In turn, this can improve supply chain management performance as well.

IIoT and ERP integration is also proven to enhance overall quality control by providing real-time monitoring of production processes. The sensors collect information on temperature, pressure, humidity and more to identify any potential problems before they arise. It helps companies reduce scrap and rework while increasing product quality as well as customer satisfaction.

IIoT and ERP integration also provides another advantage by automating processes. IIoT devices can be programmed to trigger actions in ERP systems, such as ordering raw materials when inventory levels reach a set threshold. It eliminates manual intervention while saving both time and reducing associated risks.

Integration between IIoT devices and ERP systems can bring immense advantages for manufacturing businesses. By harnessing data collected by IoT sensors to access ERP systems, companies can make data-driven decisions, streamline operations, improve quality control measures and reduce costs while remaining competitive in an ever-evolving marketplace. IIoT and ERP integration will become ever more crucial as manufacturing industries adapt over time. If you are thinking, the below segment can give you clarity.

Transform your manufacturing operations with IIoT integrated ERP. Embrace the future of manufacturing with Silent Infotech. Boost efficiency, optimize productivity, and drive growth.

Check out how our IIOT enable Seafood ERP software solve the problem faced by seafood industry and how it help seafood industry to better track and manage seafood.

CASE STUDY: SEAFOOD IIOT INTEGRATED ERP SOFTWARE

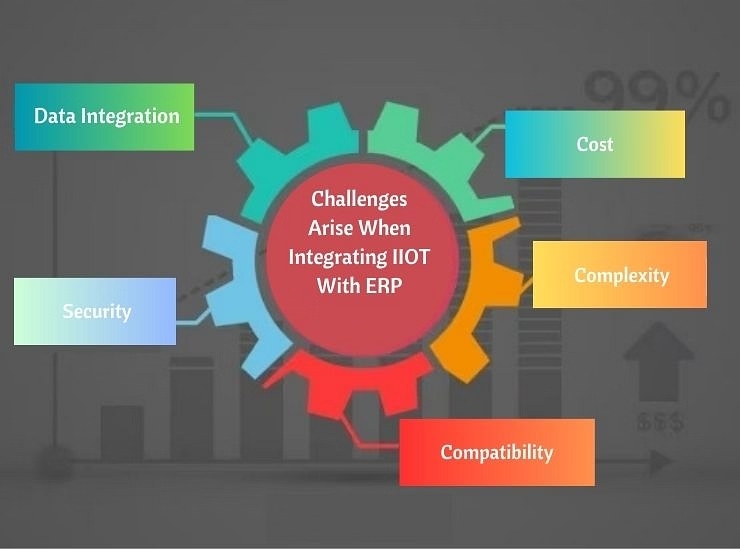

Data Integration:

One of the primary challenges involved with integrating IIOT devices and ERP is data integration. These IIOT devices generate huge volumes of information that must be properly translated for understanding by ERP systems – this requires considerable expertise, time, and work.

Security:

Integrating IIOT devices with ERP can present additional obstacles due to being connected directly to the internet and vulnerable to cyber-attacks, so robust measures need to be put in place in order to safeguard against data breaches or any potential security threats.

Compatibility:

IIOT devices and ERP systems may have been created by different vendors and may not be compatible. Integrating them can require significant customization efforts that take both time and money to accomplish successfully.

Complexity:

Integrating IIOT systems with ERPs can be complex and demanding of time and resources to maintain, making implementation difficult for businesses with limited knowledge or staff available for this work. Managing this complexity effectively may prove problematic as businesses try to implement and operate these systems successfully.

Cost:

Integrating IIOT systems with ERPs can be expensive, necessitating major investments in hardware, software and expertise – this cost may present an insurmountable barrier for small and mid-sized businesses that lack sufficient funds to purchase such systems.

Future of Manufacturing with IIOT And ERP

Here are just a few ways that IIoT and ERP are shaping the future of manufacturing:

Real-Time Data Collection and Analysis:

IIoT sensors and devices can collect real-time information regarding machine performance, production rates and other key indicators of machine effectiveness and production efficiency for analysis by ERP systems in real-time to pinpoint inefficiencies, predict maintenance needs and optimize production processes.

Predictive maintenance:

IIoT sensors can identify when machines need maintenance before they break down, helping avoid expensive downtime and repairs. ERP systems then schedule these maintenance appointments automatically so machines are running at peak performance levels at all times.

Supply chain optimization:

IIoT sensors enable businesses to monitor products and materials in real time, giving an overview of their supply chains. ERP systems then use this data to optimize inventory levels, reduce wastefulness and speed delivery times.

Improved Quality Control:

IIoT sensors enable quality assurance at every stage of production – from raw materials through finished goods – with ERP systems using this data to identify and resolve quality issues before they become major headaches.

Improved Safety:

IIoT sensors can identify potential safety risks such as machine malfunctions or chemical spills and alert workers of possible danger. ERP systems then track safety incidents to make sure appropriate procedures are being adhered to.

Conclusion

IIOT in ERP systems is revolutionizing manufacturing. Being able to collect and analyze real-time manufacturing process data allows for more effective decision-making; predictive maintenance capabilities reduce downtime while increasing productivity; further advancements and advancements should become possible as we see even greater use. Ultimately, IIOT helps manufacturers stay competitive in an ever-evolving global marketplace. Good luck!

Challenges Arise When Integrating IIOT With ERP

Integration between IIOT and ERP systems has grown increasingly popular over time, offering numerous benefits while creating some challenges associated with its implementation. This article will outline several of those barriers related to connecting IIOT and ERP.

Jignesh V

Jignesh Vaghasiya, COO of Silent Infotech, is a technology visionary with a passion for innovation. He has deep technical expertise and a commitment to client success to drive the company's growth. His relentless pursuit of new technologies, combined with his process-focused approach, has led to innovation and technology implementations that boost business outcomes. Jignesh's ability to connect with people makes him the ideal partner for onboarding new clients and fostering strong business relationships.

Schedule Consultation with Jignesh Schedule Now