How to Future-Proof Your Warehouse Technologies?

Revolution has left no industry untouched. Warehouses are not an exception too. Since the logistics industry started evolving, warehouses have adopted new and advanced technologies to keep up with this fast-paced world. While e-commerce sales are increasing highly, making the whole supply chain system complex, warehouses face more challenges and necessities to transform themselves into future-proof.

Keeping your warehouse prepared with the latest technologies and opting for

Upgrading Warehouse for Future Betterment

There are numerous ways to transform your warehouse to make it future-proof. Using the most recent market advancements, innovative technologies like robotics and artificial intelligence could transform the whole scenario from manual to digital. Automated decision-making by analyzing data could do the job too.

According to the recent survey report presented by the MHI Annual Industry Report, 80% claim that the digital supply chain will be considered the ruling model in the coming five years. Whereas the other 20% claim it already becomes a superior model.

So, it’s high time that you start looking forward to the future and make your way of adapting warehouse digitalization.

What Advancements Warehouse Technologies Can Provide to Businesses?

Acknowledging smart warehouse technologies is necessary to ensure your business can combat future technological advances and business operations run smoothly without interruption. Look at the technical aspects that can take your business to new heights.

Role of Real-Time Data Management and Better Interconnectivity

The current warehouse and supply chain systems could only work efficiently in the coming days with automation. Blockchain, on the other hand, has extreme potential for offering transparency at each level. By distributing information securely and fast, this technology makes real-time data management effort-free, efficient and translucent. Blockchain must still be completed with the Internet of Things (IoT).

We know it isn’t easy to perform a complete future prediction. Still, it is for sure that this warehouse automation technology can utilize the correct data effectively and would bring customized solutions for each business to ensure better connectivity.

Role of Warehouse Mobility

World has seen a massive transition from work desktops to smartphones. Today, smartphones can do almost anything. These mobile devices for smartphones are great to be in the era of gaining proficiency in warehouse technology. Because of the advanced and worthwhile apps, employees and warehouse managers can access the data of warehouse work anytime and anywhere. Even these data are accessible outside of the warehouse.

Smartphones are freeing people from desktop bounded activities and making them more eligible to work efficiently in different plants, facilities, and workstations. Warehouse mobile solutions are an ideal example of that. It can deliver excellent results based on the warehouse operators’ needs.

Role of the Internet of Things (IoT)

IoT is the future. It is an effective system connected to various digital networks. According to the predictions, worldwide spending on IoT will be 1.1 trillion by the end of 2023. That means the Internet of Things (IoT) has this worth and potential in the global market. It works to connect devices to the internet and allows a smoother communication process.

The more IoT is used in different markets, the better people are getting familiar with this. IoT also plays a massive role in the data transformation in the data warehouse. IoT is highly effective in monitoring your inventory, even from your smartwatch. It is behind the easy access system that can be checked from a phone, laptop, or any other device.

Role of Artificial Intelligence and Machine Learning

Artificial intelligence (AI) is about executing results based on various algorithms and behavior. AI can run independently, the main difference between computer operating manual programming and artificial intelligence.

In warehouse management, AI works on operational efficiency, reduces production costs, and also increases safety. Robotics are programmed with deep learning algorithms that robots understand to recognize their commands and execute the outcome. These robots know which product is for packing or unpacking by checking the codes or RFID tags.

AI technology can eliminate human error while performing warehouse tasks. As a result, businesses can observe a higher level of accuracy besides working quickly. You can trust Ai blindly, as these machines never make mistakes like humans. As they never get tired, there are no chances of errors.

Role of Autonomous Guided Vehicles

AGVs (Autonomous Guided Vehicles) have still not been widely adopted, but it is predicted that India’s AGVs market will reach around $364.3 million by 2027. It means it has the potential to substitute for factory removal equipment. It could revolutionize how trucks and cargo do warehouse transport jobs.

Drone technology is also playing a pivotal role in the warehousing industry. The talk is about cost-effectiveness and safety; drones do a great job. Drones can do a commendable job of locating cargo, keeping an eye on inventory, performing and updating stocks, and running different warehouse operations. Drones can even reach the most profound spaces, fully equipped with sensors, barcode scanners, and cameras and integrated with RFID technology. The time that is required for manual options is saved with drone automation.

Role of Automation and Robotics

Warehouse automation is just the beginning of the future’s digital transformation. Data transformation in data warehouses is also a part of automation and robotics. These are connected and work to simplify the processes for excellent outcomes. Manual task performances can be done better within a short time and at a low cost.

Robotics can work better than humans based on different aspects, and it is predicted because of excellent memory, sensing power, management skills, knowledge, and infinite learning without being programmed for particular tasks.

Even with the survey conducted by Mordor Intelligence, it is predicted that the Indian market in warehouse robotics automation will see a surge by reaching USD 682.1 million in the coming five years.

Is your current warehouse management software lacking advanced features or causing issues in your warehouse and inventory management processes? Our team of experts is here to help. Schedule a consultation with us to discuss your challenges and explore the best software solution tailored to your specific needs.

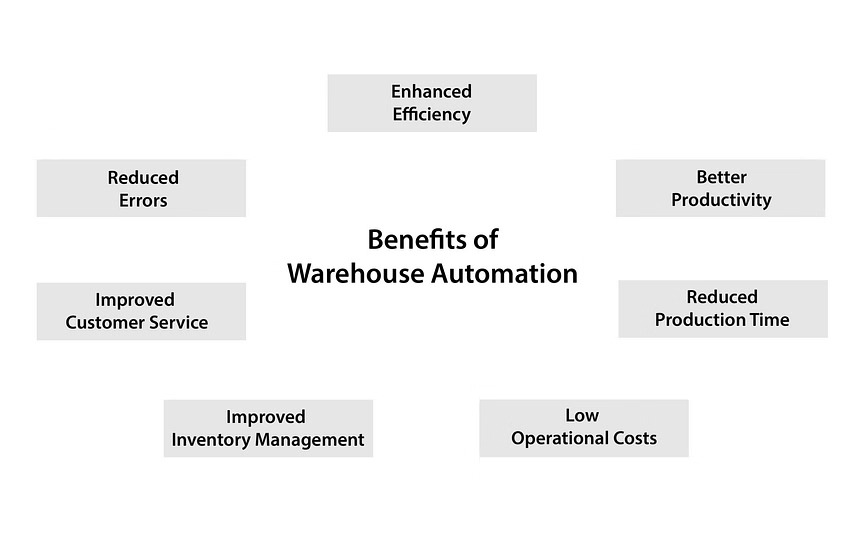

What Are The Benefits Of Warehouse Automation in the Business?

Optimizing supply chains has become an integral part of the warehouse. Automation is necessary as it brings different benefits. From reducing time, labor, cost, and error-free results due to manual operations, warehouse automation with a data warehouse update strategy plays a prime role in building your business’s future.

According to the survey reports by Mordor Intelligence, the automation market of India is predicted to reach USD 682.1 by 2028. Every warehouse has to keep up with the competitive market, which is why automation has become necessary. As a result, the warehousing industry will see a surge soon.

Reduced Errors

The e-commerce market is one of the most popular platforms for shopping. But these companies often cause disasters by delivering the wrong orders to consumers. It is the breaking point when consumers start losing faith in the company. Warehouse automation can simplify the process of arranging orders. Human errors in shorting orders and packing wrong products could be reduced too with improved order accuracy.

Though no system can be claimed to be 100% accurate, automation certainly improves the accuracy level. Automated systems can quickly identify and correct such errors to smooth the business process.

Enhanced Efficiency

Automation is not about replacing human employees with robots but about doing the same tasks more efficiently and with less hassle. Warehouse automation has the potential to bring employee satisfaction, making their work error-free and encouraging them to provide value-added services. In other words, you can thanks to warehouse automation, as it reduces the time of repetitive tasks and unnecessary resource wastage.

Warehouse automation also brings a significant impact when businesses face a rush in periods like sales or holidays. Besides this, as your employees are already eligible to perform their tasks efficiently, there is no need to hire temporary workers as an add-on. As a result, cost-effectiveness.

Better Productivity

The speed of robotics can not be matched with humans. At the same time, robots can not replace the IQ levels of humans. So, both are qualities necessary for effective business formation. As most warehouse tasks are time-consuming and repetitive, warehouse automation could bring a huge change. It comes under the data warehouse update strategy, as updating data manually for similar tasks is unnecessary.

From moving goods to packing and even unpacking, the whole process gets simplified and automated due to the advancements of automated software. As a result, the overall productivity improved in a highly advanced way.

Reduced Production Time

Warehouse automation is excellent for speeding up the complete process of product management. From packing to shipping, there are different phases in product handling. It also takes a lot of time. Indeed, humans can not match the speed of robotics.

Warehouse automation systems accurately handle the products and ensure the weight, dimension, and image in just a fraction of a second. It could do wonders when you have to take thousands of parcels quickly. On the other hand, the automation process of warehouses optimizes the workflows so that everything gets done without interruption. This system has made the automation process an essential one.

Improved Inventory Management

Customers always expect faster shipping, which is why supply chains face challenges. Balancing between supply and consumer demand is extremely tricky. So, it is better to invest in warehouse automation rather than managing the tasks manually. From inventory management to preventing the shortage of goods and opting for the correct production, warehouse automation offers many things a business should not miss.

AI automation is used to crack inventory information and apply intelligence to show relevant product information. Thus, precise decisions enable employees and product managers to perform their jobs more accurately.

Low Operational Costs

Though investing in warehouse automation is expensive, evaluating the cost of this automation process may seem costly at first, but later you will find its worth. Investing in such an automation system rather than bringing fatality to business is better.

These automation systems are also highly popular for great ROI and offer different options for savings. Reducing staff costs to training charges, product handling and storage expenses, and even optimising the inventory and risk of product loss.

Improved Customer Service

In this competitive market, satisfying customers’ products and services is critical to your business’s success. These days, companies are highly proactive and try to serve consumers better than their expectations of increasing turnovers.

Here smart warehouse technologies reduce the timing for order preparation and shipping, lowering errors to almost zero. If a customer wants to return their product, automation in the return system is also applicable.

Conclusion

Technology is evolving in every market, offering growth to almost every business. It’s time to adopt new innovations too for your warehouse business. You are losing opportunities if you have to convert your warehouse to a digital one. Warehouse management software is the critical thigh that your business needs at this moment. So don’t miss the opportunity and take the path of automation to achieve success in your business in the long run.

| About Author

Rajesh R

A seasoned IT Integrations and ERP Solution Architect boasts over a decade's expertise in revolutionizing business processes through cloud-based ERP and MIS software solutions. Proficient in leveraging avant-garde technologies such as Blockchain, Al, IoT, etc in crafting bespoke software solutions. His extensive background encompasses tailor-made software solutions across diverse industries like Sales, Manufacturing, Food Processing, Warehouse Operations→ and B2B Businesses. Rajesh excels in engineering and deploying enterprise-grade business software, playing a pivotal role in Business Solution Consulting and designing intricate software solution architectures for many Fortune 500 enterprises.

Schedule Consultation with Rajesh Schedule Now