With many moving parts and different stages of development, the manufacturing industry’s production process can be a complicated and intricate affair. Manufacturers have to produce goods that are of the highest caliber while minimizing costs and guaranteeing prompt customer delivery. Manufacturers, however, face a variety of difficulties that can make this process more challenging. Enterprise resource planning (ERP) software, fortunately, makes it possible to overcome many of these difficulties.

We will look at a few of the challenges faced by manufacturers in this blog post, as well as how ERP can help address those challenges. Additionally, some advantages of using

Difficulties Faced By Manufacturers

Inventory Management

The ability of manufacturers to effectively manage their inventory is one of their biggest challenges. Managing numerous products and components can make it difficult to keep track of everything. However, manufacturers can easily keep track of their inventory levels and determine when to place new orders for goods or components with the aid of an ERP system. To ensure they have enough inventory to meet demand without overstocking and using up capital, they can also optimize their inventory levels.

Quality Control

Another crucial component of manufacturing is quality control. To prevent recalls, bad reviews, and reputational harm, manufacturers must make sure their products adhere to the highest standards of quality. Without an effective quality control system, this can be difficult. Manufacturers can implement quality control processes and procedures with an ERP system to make sure every product complies with the required standards.

Scheduling and Planning

Due to the time-sensitive nature of manufacturing, planning, and scheduling are essential to guarantee on-time delivery of the finished goods. Manufacturers can make plans and schedules for each step of the production process with the aid of an ERP system. They can also keep an eye on developments in real-time and adjust things as needed to keep things on course.

Data Management

Any manufacturing process needs to have effective data management. To make wise decisions about production, sales, and marketing, manufacturers must gather and analyze data from a variety of sources. Without the proper tools, managing all of this data can be difficult. By gathering and storing all of a manufacturer’s data in one place, an ERP system can assist manufacturers in managing their data effectively. They can then use this information to learn more about their operations and come to well-informed conclusions.

Communication and Collaboration

Manufacturing is a team endeavor, and success depends on effective communication and collaboration. However, it can be difficult to keep everyone on the same page when numerous teams are involved in various aspects of the production process. By giving teams a central location to share documents, files, and updates, an ERP system allows manufacturers to improve communication and teamwork. This can increase overall output and guarantee that everyone is striving for the same objectives.

Compliance and Regulation

Manufacturers are required to adhere to several laws and standards that affect their operations and products. For smaller manufacturers without dedicated compliance teams, this can be difficult to navigate. However, by tracking and monitoring regulatory requirements and ensuring that they are met, an ERP system can assist manufacturers in managing compliance. By doing this, compliance problems and potential fines may be avoided.

Cost Management

Cost management is essential to ensuring profitability because manufacturing can be expensive. However, it can be difficult to keep track of everything because there are so many costs associated with the production process. Manufacturers can more effectively track and manage their costs with an ERP system. They can pinpoint areas where costs can be cut, like optimizing inventory levels or raising production efficiency.

Experience any challenges with your manufacturing business?

Discover the missing features in your current ERP system. Connect with us now for a free consultation and unlock the potential of our comprehensive ERP solutions.

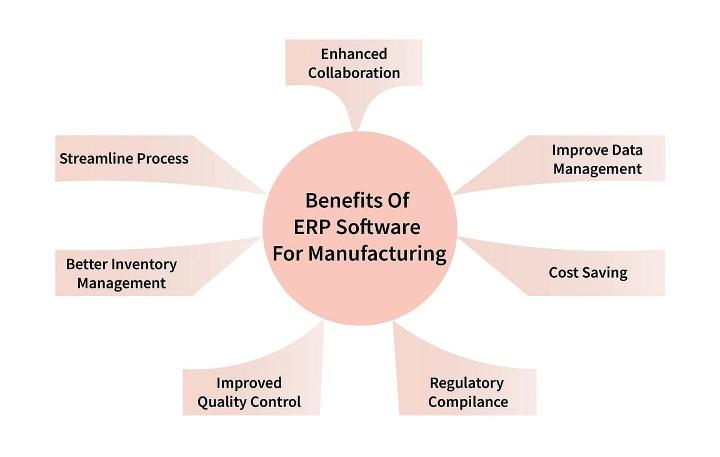

Benefits of Using ERP Software For Manufacturers

For manufacturers facing these difficulties,

Streamlined Processes

By automating repetitive tasks, cutting down on errors, and increasing effectiveness, ERP software can aid in streamlining processes. Through the automation of monotonous tasks, the reduction of errors, and increased effectiveness, this streamlined processes ERP software can assist in streamlining processes. This can increase productivity for manufacturers while also helping them save time and money. ERP software can decrease the amount of manual work required by automating processes like inventory management and scheduling, freeing up employees to concentrate on more strategic tasks.

Improved Data Management

Data management is essential to the manufacturing process, as was already mentioned. Manufacturers can more efficiently gather, store, and analyze data if they have an ERP system in place. This can assist them in identifying opportunities to increase efficiency and cut costs, as well as better decisions about production, sales, and marketing.

Enhanced Collaboration

Every manufacturing process requires efficient teamwork, and ERP software can make this happen by giving groups of people a central location to communicate and share data. ERP software can assist manufacturers in reducing errors and enhancing general productivity by enhancing communication and teamwork.

Better Inventory Management

ERP software can assist manufacturers in managing their inventory levels more efficiently. Inventory management is an essential component of manufacturing. Manufacturers can optimize their stock levels to meet demand without overstocking or using up capital by providing real-time visibility into inventory levels

Improved Quality Control

To make sure that products adhere to the necessary standards, quality control is crucial. Manufacturers can implement quality control processes and procedures to ensure that every product complies with the necessary standards if they have an ERP system in place. The likelihood of a recall and reputational damage can both be reduced as a result.

Regulatory Compliance

Manufacturing companies face a serious problem with compliance, and ERP software can assist in making sure that manufacturers adhere to the necessary laws and standards. ERP software can assist manufacturers in avoiding regulatory compliance issues and potential fines by tracking and monitoring regulatory requirements.

Cost Savings

By optimizing inventory levels or enhancing production process efficiency, ERP software can assist manufacturers in identifying areas where costs can be decreased. Manufacturers can boost profitability and finance expansion strategies by reducing costs.

Conclusion

In conclusion, ERP software can make the complex and difficult process of manufacturing more manageable. ERP software can assist manufacturers in overcoming many of the challenges they face by streamlining processes, improving data management, enhancing collaboration, managing inventory more effectively, improving quality control, ensuring regulatory compliance, and lowering costs. Manufacturers can increase productivity, decrease errors, and set themselves up for long-term success in a fiercely competitive sector by investing in ERP software.

A strategic choice that can give manufacturers a competitive edge is to implement an ERP system. Manufacturers can increase productivity, decrease errors, and boost customer satisfaction by streamlining operations, improving data management, fostering collaboration, managing inventory more effectively, ensuring quality control, adhering to regulations, and cutting costs.

ERP software can assist manufacturers in identifying areas where costs can be reduced and profitability can be increased, as well as in responding more quickly to changing market conditions and customer demands. Making decisions based on real-time data can be a game-changer for manufacturers, allowing them to streamline processes, boost output, and provide customers with high-quality goods.

Companies must change as the manufacturing sector develops if they want to remain competitive. By giving manufacturers the resources, they need to improve productivity, cut costs, and streamline operations, ERP software can help manufacturers stay ahead of the curve. Manufacturers can set themselves up for long-term success in an ever-changing and difficult industry by investing in ERP software.

Jignesh V

Jignesh Vaghasiya, COO of Silent Infotech, is a technology visionary with a passion for innovation. He has deep technical expertise and a commitment to client success to drive the company's growth. His relentless pursuit of new technologies, combined with his process-focused approach, has led to innovation and technology implementations that boost business outcomes. Jignesh's ability to connect with people makes him the ideal partner for onboarding new clients and fostering strong business relationships.

Schedule Consultation with Jignesh Schedule Now